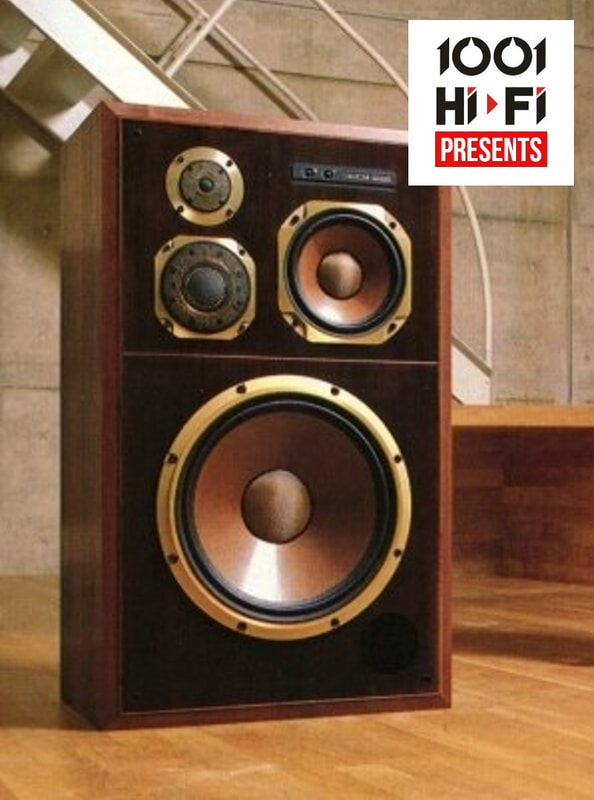

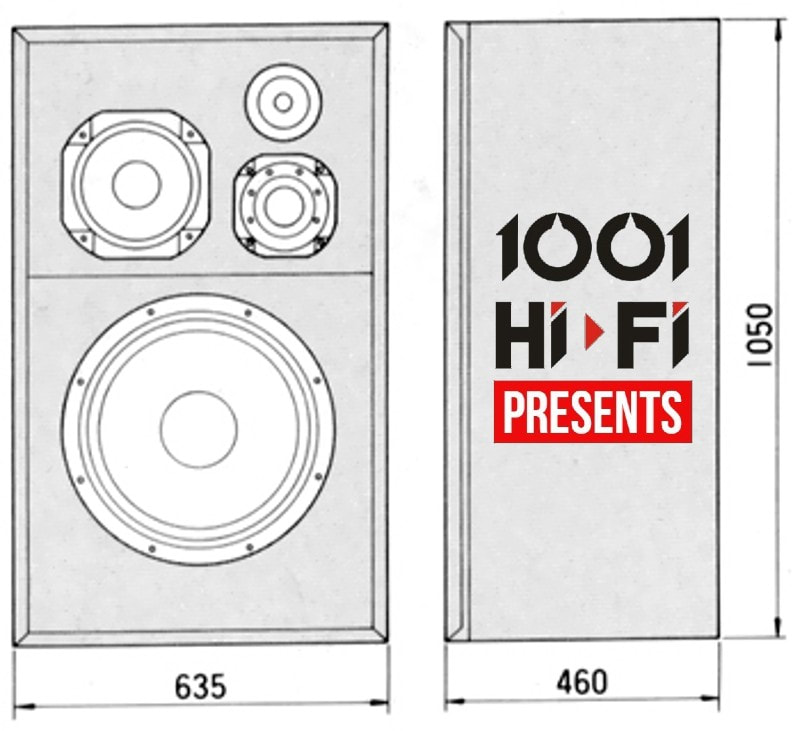

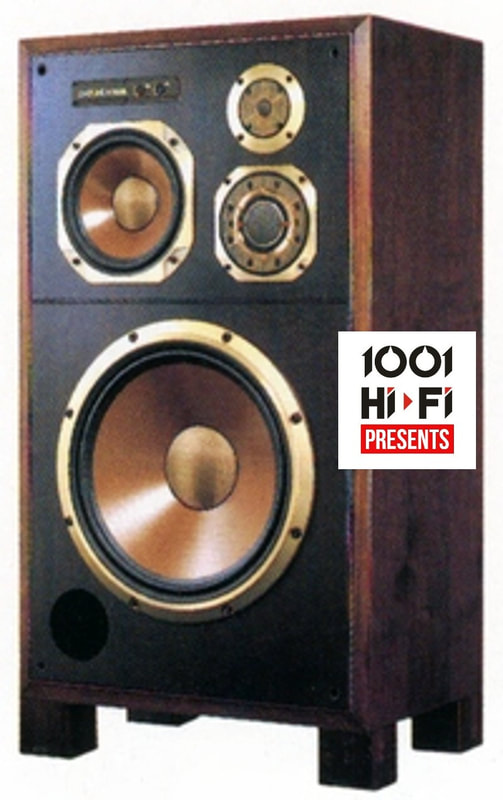

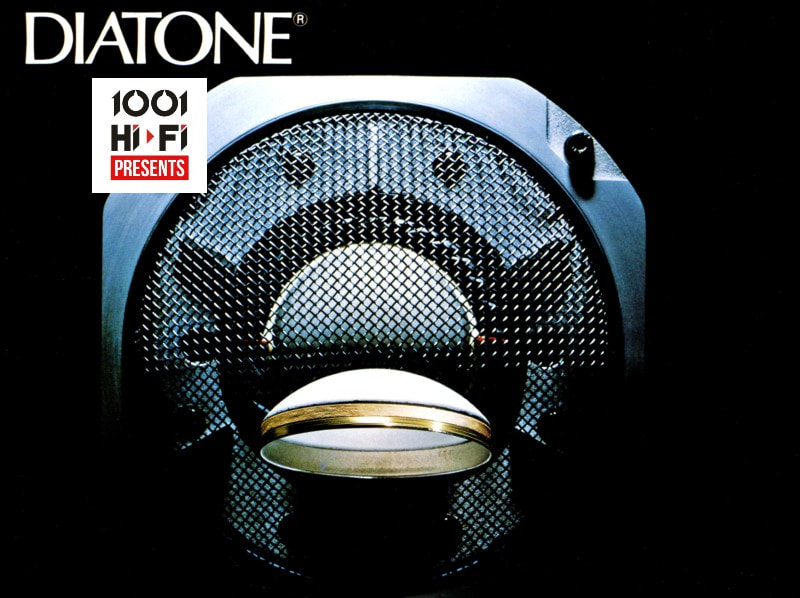

DIATONE DS-5000 (JAPAN 1984)

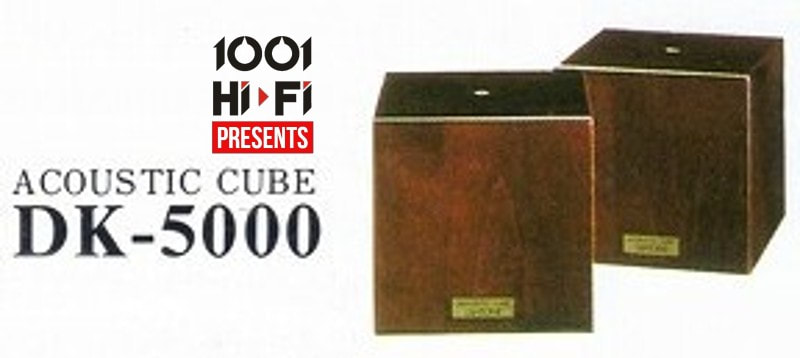

Diatone is a registered trademark of Mitsubishi Electric Japan, used for audio-visual equipment and it's one of Japan's leading speaker brands. In 2016 the brand celebrated its 70th Anniversary. The Diatone trade name was used for the first time in 1946 while the Diatone DS-5000 was introduced as a flagship loudspeaker model in 1982. This bass reflex system loudspeaker is made of lauan plywood and it houses a 40cm aramid fiber honeycomb cone bass, 25cm aramid fibre honeycomb bass-mid, 6.5cm boron coated titanium dome D.U.D. diaphragm for mid-high and a 2.3cm boron coated titanium dome D.U.D. diaphragm for tweeter. (D.U.D. - Diatone Unified Diaphragm). The frequency range of this loudspeaker is 20Hz to 60 kHz while the 635x1050x460 mm enclosure weighs a whopping 87 kg. A special accessory, the DK 5000 acoustic cube made of Canadian maple was sold separately (8 pcs. 1 set) as speaker vibration block. Maximum input power of the loudspeaker is 250W, impedance 6 ohm and the crossover frequencies are at 300Hz, 1.25kHz and 4kHz. The loudspeaker is equipped with adjustment for room acoustic in the form of L-pads for mid and high frequencies. In 1987 the Diatone merged with Akai Electric (AKAI) which joined Mitsubishi Group due to a financial crisis, and established the joint brand A&D (Akai&Diatone). After the disappearance of the A&D brand in 1991 Diatone adopted the form of made-to-order manufacturing.

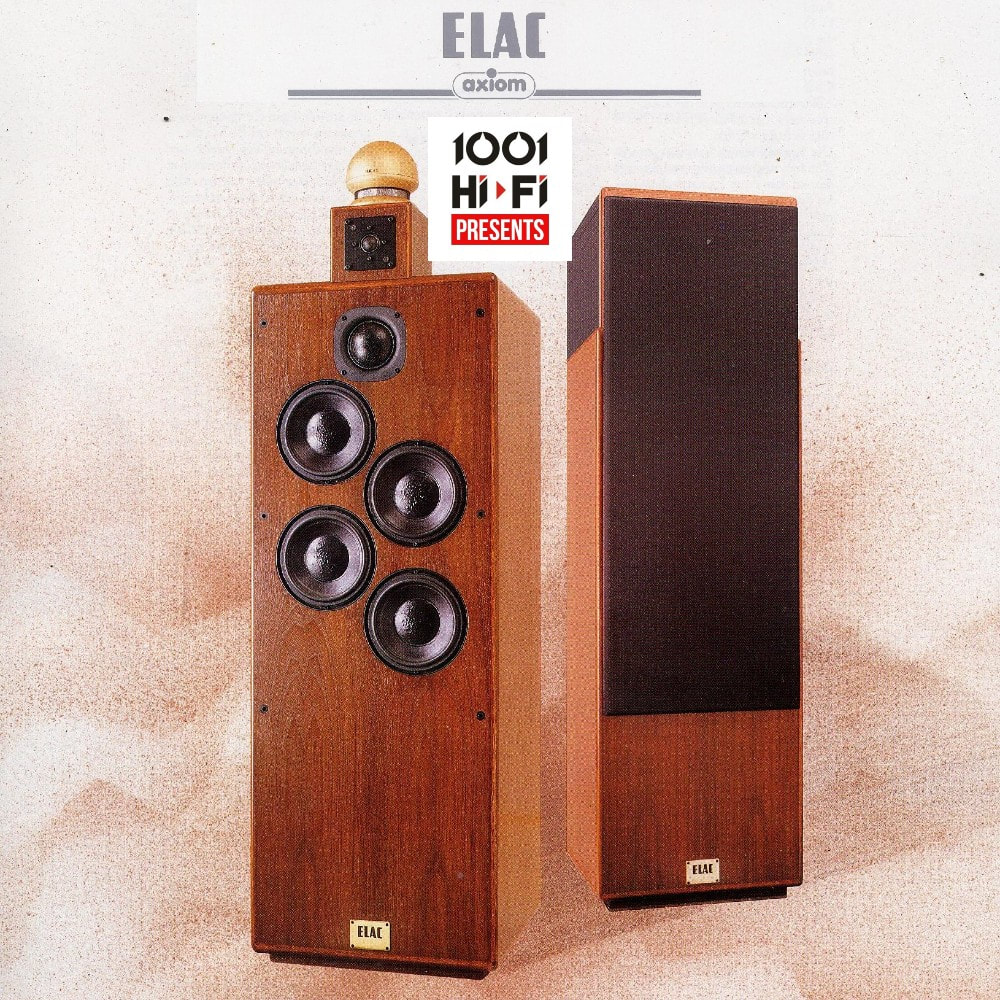

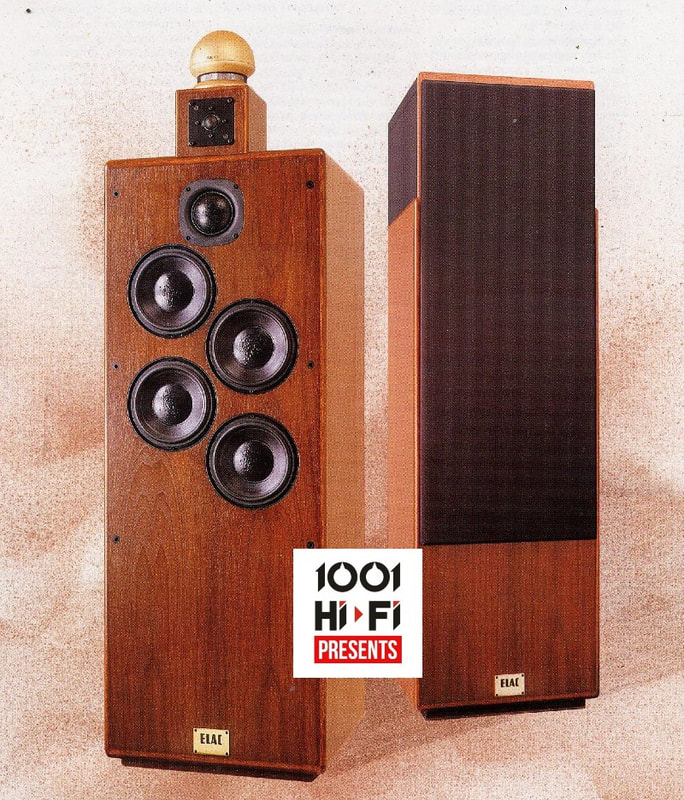

ELAC 250 4Pi (GERMANY 1985)

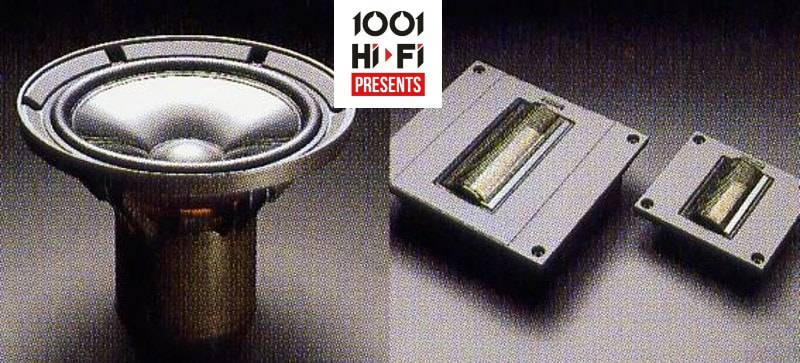

The ELAC 250-477 loudspeaker system was designed as a 4-way unit. Each of the loudspeaker chassis used only has to transmit the frequency range in which it works best. The playback quality is clearly audibly better because the amplitude frequency response (the evenly loud playback of all frequencies from the deepest bass to the highest treble), the phase behavior and the directional characteristics are optimal. The - compared to conventional three-way systems - smaller frequency band, which is transmitted by the speaker chassis, eliminates the otherwise frequently heard sound discoloration in the mid-range, for example, and the sound radiation is more even, less directed. The low frequencies are transmitted up to around 550 Hz by four small special low-frequency drivers. The comparatively small cones are lighter and more stable than those with a larger diameter. The lower dead weight and the powerful coating due to the four large magnets result in an optimal power/mass ratio. Great acceleration is essential for the realistic bass reproduction and therefore no problem. The unintentionally precise impulse reproduction has an overwhelming effect. A total of four loudspeaker chassis - all special developments for the 250-4Pi - work in parallel, falling through the transmission line. The bass systems and the transmission line were designed in such a way that the lowest frequencies down to 20 Hz can still be reproduced cleanly.

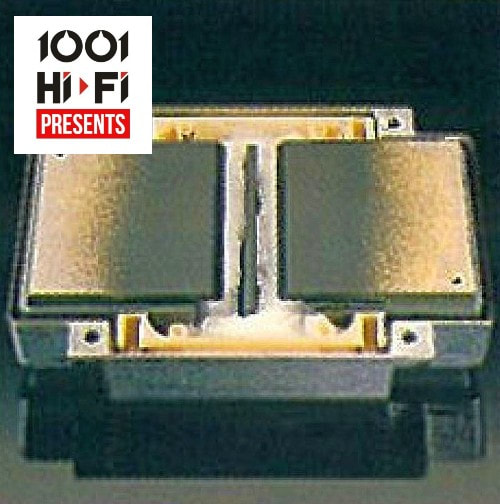

The midrange, which is so important for the natural sound image, is transmitted by two fabric dome speakers. Frequencies from 550 to 1450 Hz are reproduced by the 80(!) mm dome system. It can transmit this frequency range precisely and without distortion. The MT 25 high-midrange system, a special ELAC development, transmits the frequency range between 1450 and 4000 Hz. For the reproduction of the high tones from 4000 Hz, the 4Pi uses a technology newly developed by ELAC engineers and patented together with the Dutch group Bakker/van den Hul is used for the first time. Instead of the usual dome or cone diaphragms, a cylindrical aluminum strip that is only 5 thousandths of a millimeter (5 μm) thin is used. This extremely light cone has unmistakable advantages: an exceptional impulse reproduction is achieved thanks to the low surface weight. Only sound-radiating parts are moved in this innovative tweeter system. There are no longer any drive coils, which ignite the oscillating mass in conventional tweeter systems and thus round off the finest impulses during playback. Two powerful toroidal magnets arranged above and below the cylindrical ribbon holder generate the force field to move the aluminum ribbon. With the ELAC 4Pi technology, high frequencies are emitted evenly in the room, a basic requirement for homogeneous sound propagation in the listening room.

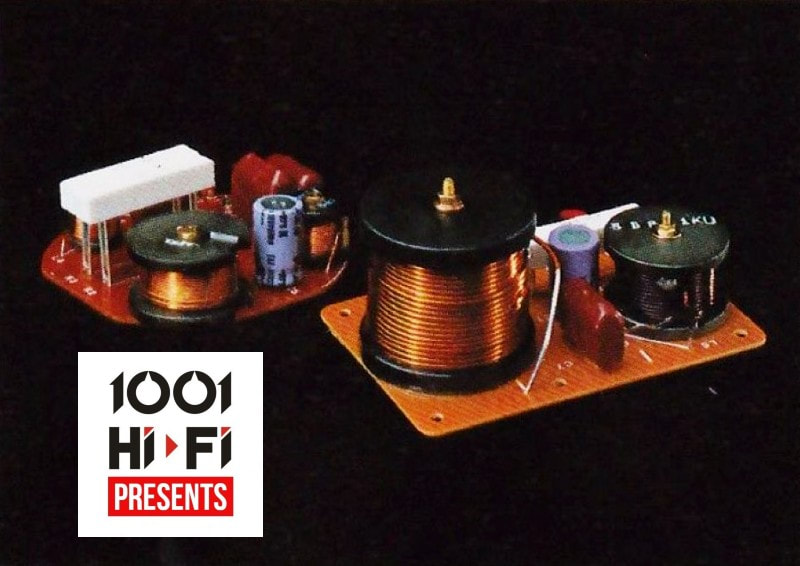

High quality crossover network. The 250-4Pi contains only selected components. The high-quality air coils are manufactured by ELAC itself - only then can the exact optimum values be maintained within the narrow tolerances specified for this high-quality speaker system. Only film capacitors are used so that the first-class sound impression is retained for years to come. They guarantee long-term stability of their physical parameters. Even the influence of the connection cables on the sound was taken into account: oxygen-free copper cables connect the chassis to the network, the network to the connection terminal. Technical data: 4-way Transmission Line | Dimensions: 1550x460x460mm | Weight:90kg | Crossover frequencies: 560/1450/4000Hz | Power: 350/250W (impulse/nominal) | Frequency range: 18-28000Hz| Sensitivity: 83 dB/1W/1m | Minimal impedance: 2.3ohm | Original sale price: 2x7498 DM, Germany.

The midrange, which is so important for the natural sound image, is transmitted by two fabric dome speakers. Frequencies from 550 to 1450 Hz are reproduced by the 80(!) mm dome system. It can transmit this frequency range precisely and without distortion. The MT 25 high-midrange system, a special ELAC development, transmits the frequency range between 1450 and 4000 Hz. For the reproduction of the high tones from 4000 Hz, the 4Pi uses a technology newly developed by ELAC engineers and patented together with the Dutch group Bakker/van den Hul is used for the first time. Instead of the usual dome or cone diaphragms, a cylindrical aluminum strip that is only 5 thousandths of a millimeter (5 μm) thin is used. This extremely light cone has unmistakable advantages: an exceptional impulse reproduction is achieved thanks to the low surface weight. Only sound-radiating parts are moved in this innovative tweeter system. There are no longer any drive coils, which ignite the oscillating mass in conventional tweeter systems and thus round off the finest impulses during playback. Two powerful toroidal magnets arranged above and below the cylindrical ribbon holder generate the force field to move the aluminum ribbon. With the ELAC 4Pi technology, high frequencies are emitted evenly in the room, a basic requirement for homogeneous sound propagation in the listening room.

High quality crossover network. The 250-4Pi contains only selected components. The high-quality air coils are manufactured by ELAC itself - only then can the exact optimum values be maintained within the narrow tolerances specified for this high-quality speaker system. Only film capacitors are used so that the first-class sound impression is retained for years to come. They guarantee long-term stability of their physical parameters. Even the influence of the connection cables on the sound was taken into account: oxygen-free copper cables connect the chassis to the network, the network to the connection terminal. Technical data: 4-way Transmission Line | Dimensions: 1550x460x460mm | Weight:90kg | Crossover frequencies: 560/1450/4000Hz | Power: 350/250W (impulse/nominal) | Frequency range: 18-28000Hz| Sensitivity: 83 dB/1W/1m | Minimal impedance: 2.3ohm | Original sale price: 2x7498 DM, Germany.

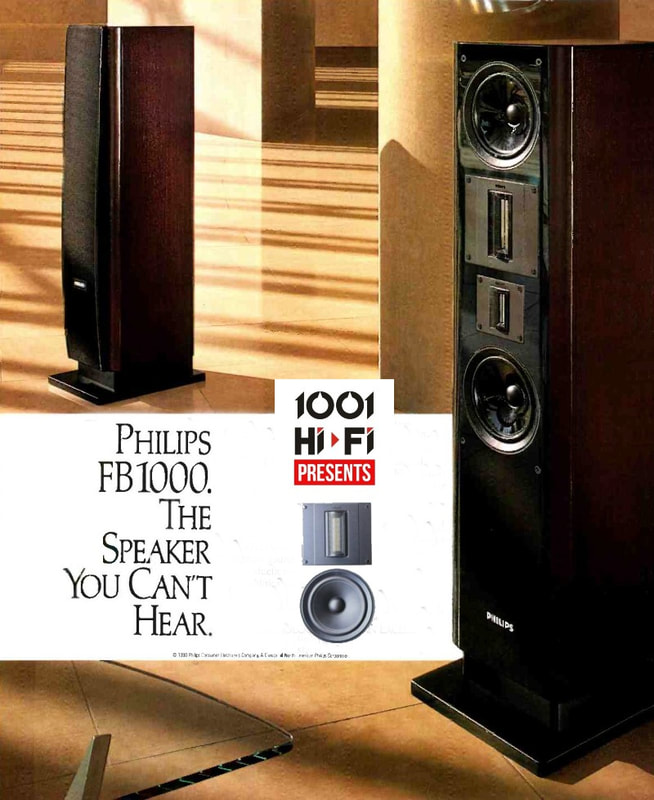

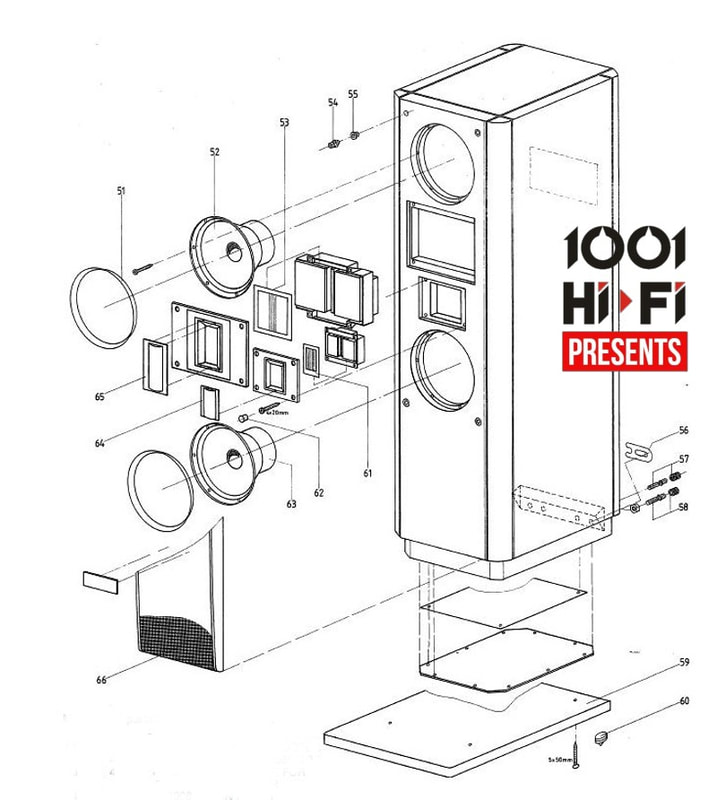

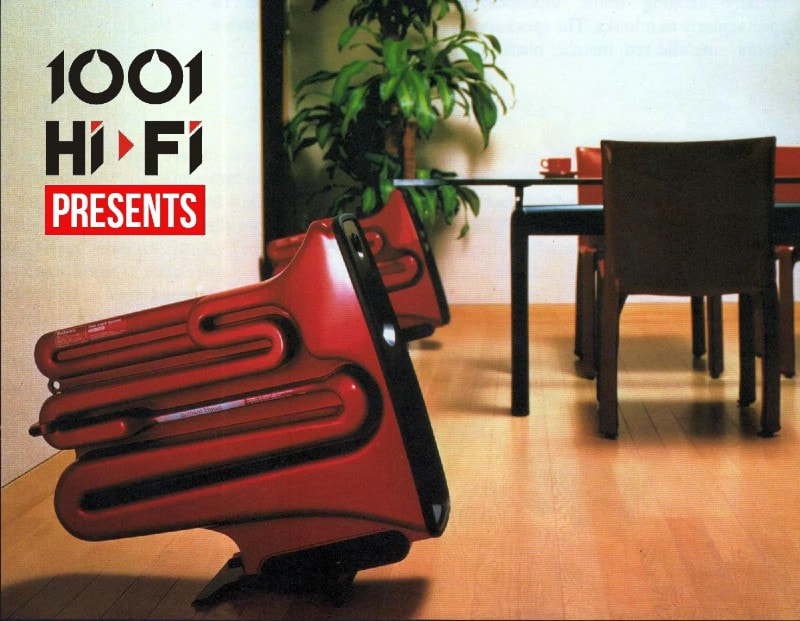

PHILIPS FB1000 (NEDERLAND 1990)

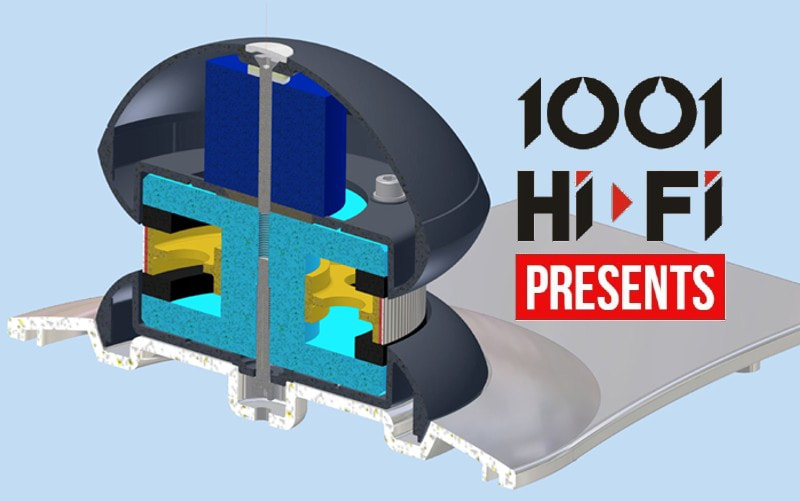

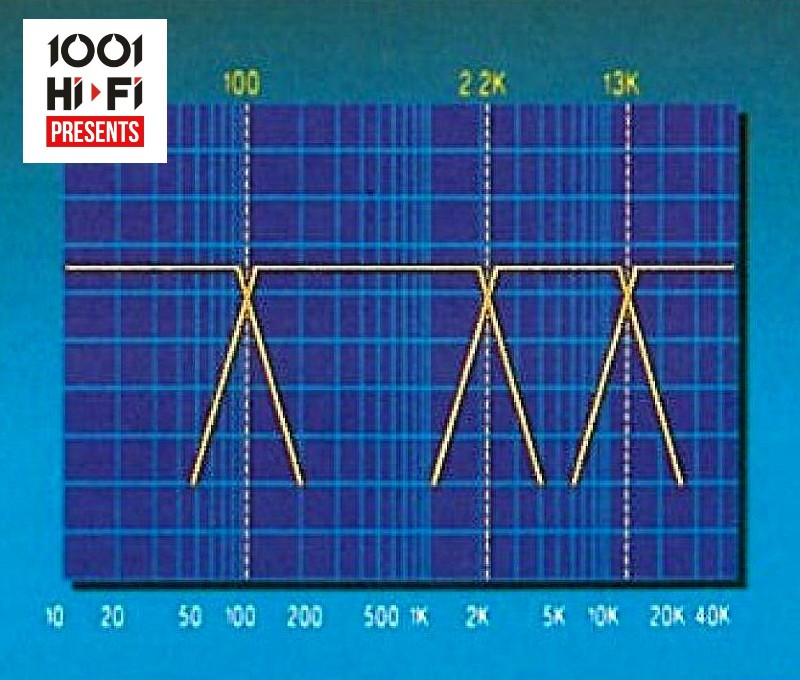

A little bit out of the ordinary, appealing to those with a specialist interest, those appreciative of the finest construction and materials. The FB 1000 is the pinnacle of PHILIPS loudspeaker design. Though incorporating four drive units the FB 1000 is basically a World-Class two-way loudspeaker. The lower two drivers (a super tweeter and second woofer) are "contour definition transducers" to provide real bass below 150Hz and to extend treble out to 40kHz. The complete four-way package is a true high-performance loudspeaker with maximum 300W high-power handling. The computer designed cabinet is divided into two independent non-parallel compartments giving an ideal air load for the two bass drivers and minimizing internal standing waves further reducing coloration. All new bass drivers have been developed for this exceptional loudspeaker. A newly developed mix of polypropylene and chopped carbon fibers is injection molded to form exceptionally rigid, lightweight cones. Low coloration, Isophase ribbon tweeters and super tweeters are used for fast transient response, low coloration and zero phase shift. A computer developed high-performance crossover integrates these drivers @ 500Hz/2,2kHz/13kHz. A rebadged version of this model was the marantz LS-95, part of their Music Link series products. Both loudspeakers were manufactured at the PHILIPS factory in Belgium. Specifications: 40 Hz -40 kHz (-6dB) / 47 Hz - 32 kHz (+/- 2 dB) / Power Nominal 180W / Max. 300 W / 1360*400*340mm / 70 kg

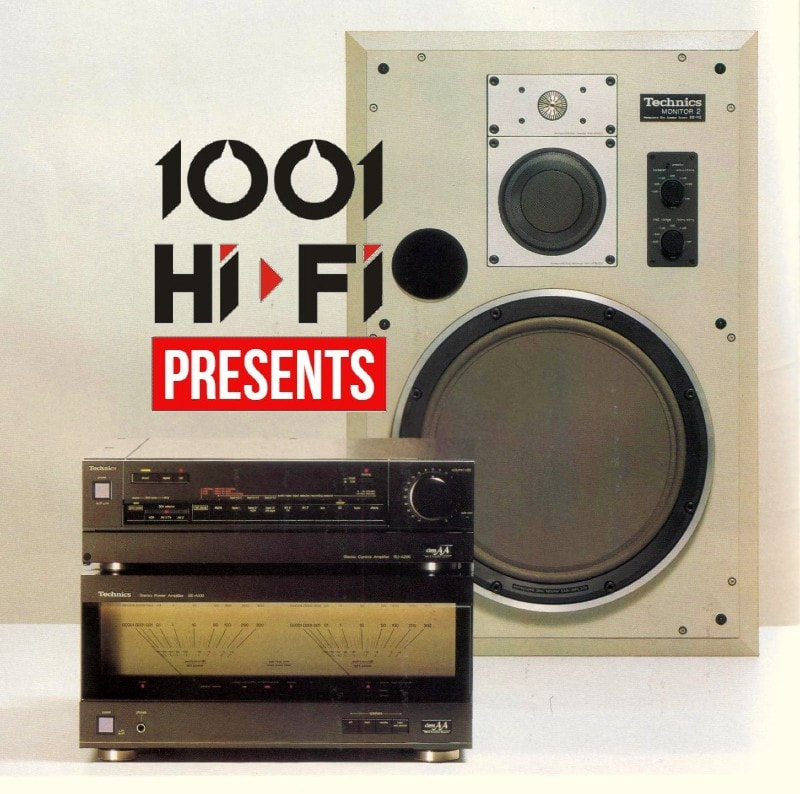

TECHNICS MONITOR 2 (JAPAN 1982)

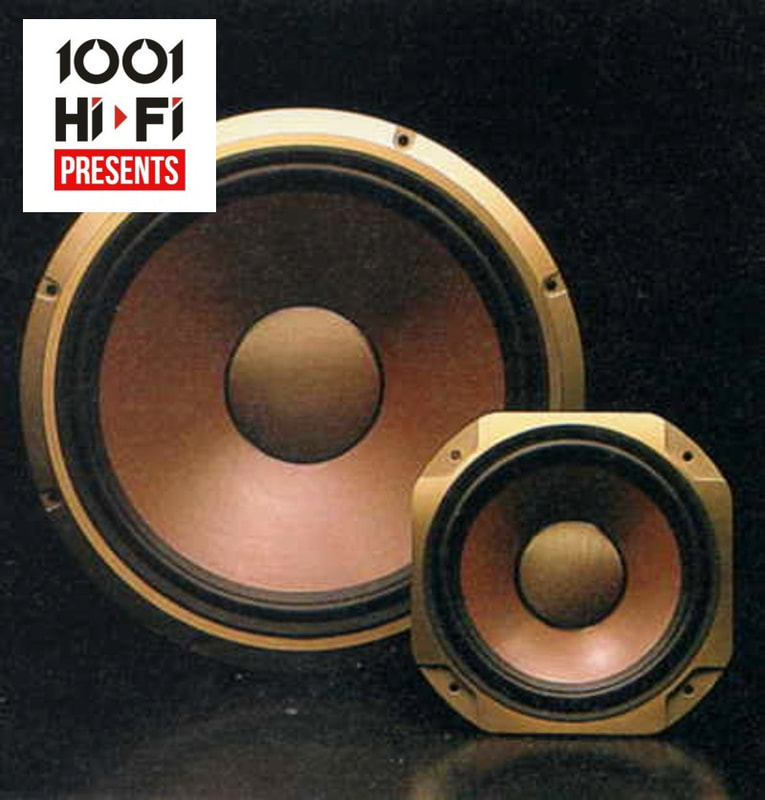

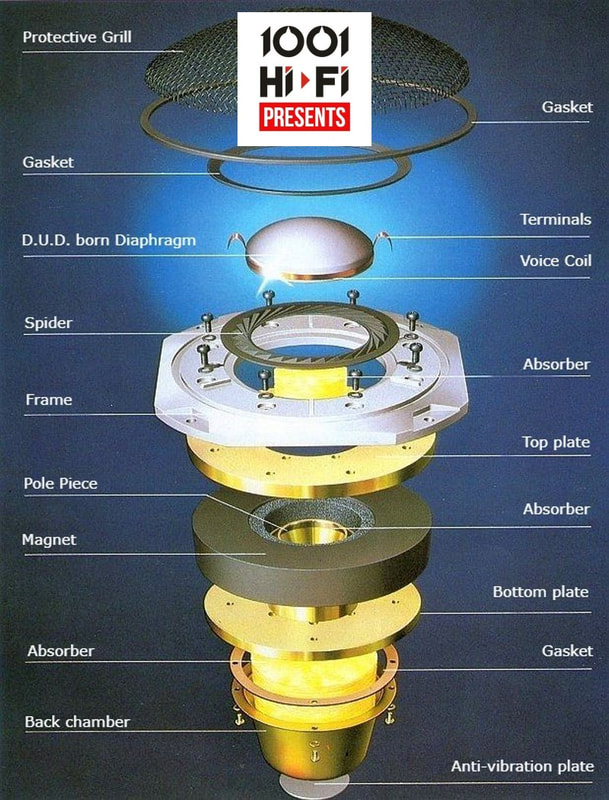

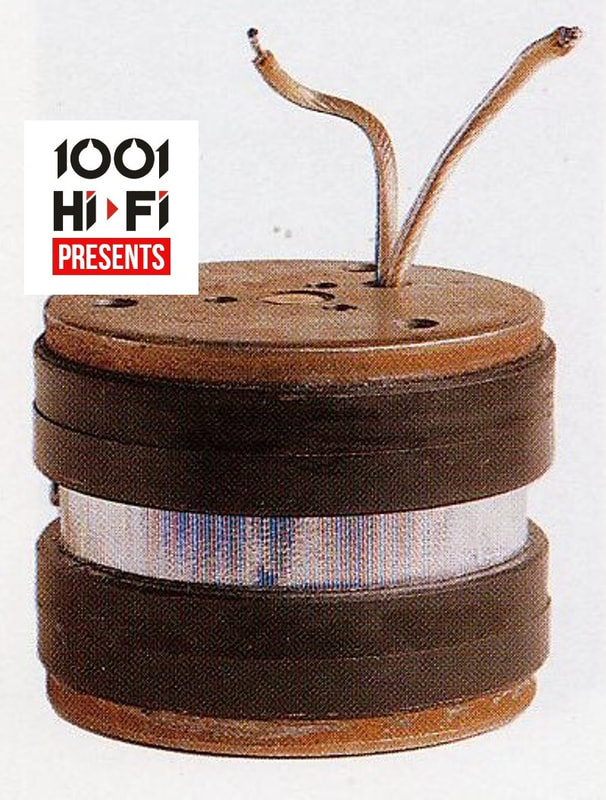

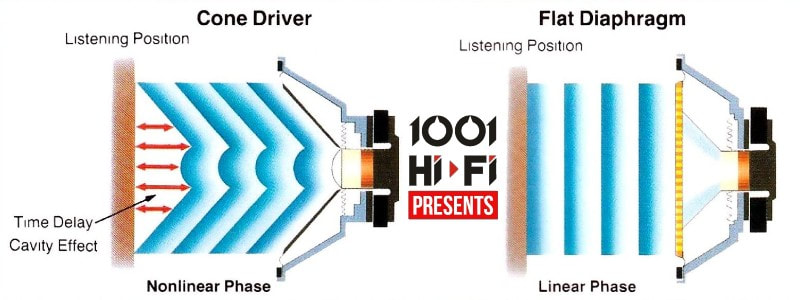

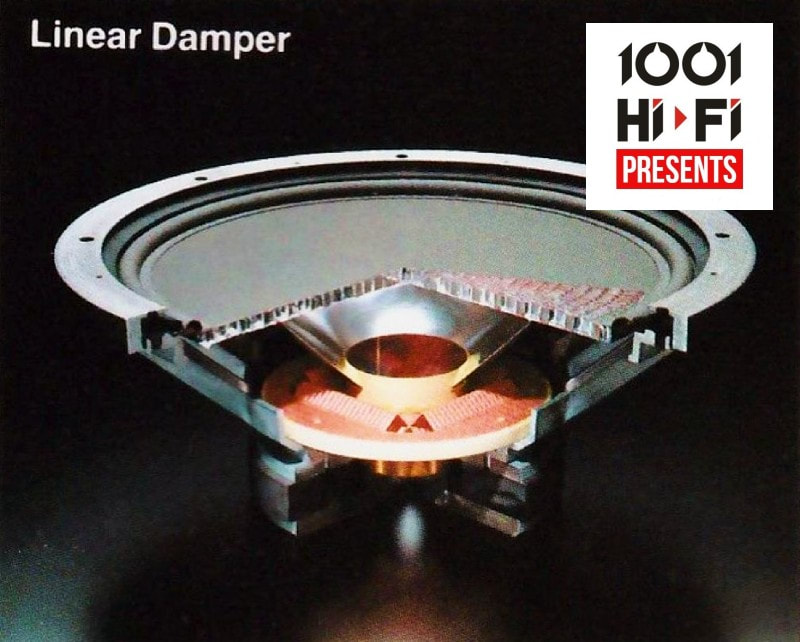

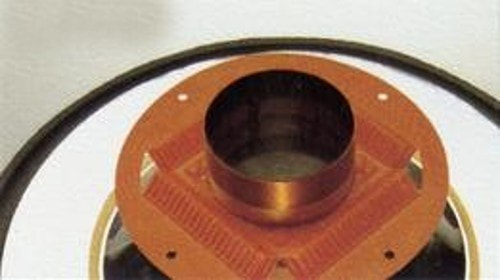

The Technics Monitor 2 (SB-M2) was introduced in 1982 as a slightly simplified version of the first Honeycomb Disc Speaker System from Technics, the Monitor 1 introduced in 1981. The Technics SB-M2 was specially developed to provide the performance required for accurate and undistorted reproduction of digital material. Specifically, this means high power handling capacity, high linearity at high input levels, and flat frequency and phase response throughout the audio spectrum and beyond. Honeycomb disc drivers are used for the woofer, midrange and tweeter in this 3-way, bass reflex system. The traditional cone shaped driver suffers from an inherent problem called the cavity effect. As a result, there is uneven frequency response as well as sound quality degradation. In contrast, the Technics Honeycomb Disc Driver is flat, so it eliminates these delays or phase irregularities. Smooth and extended low range response is a major feature of the SB-M2.

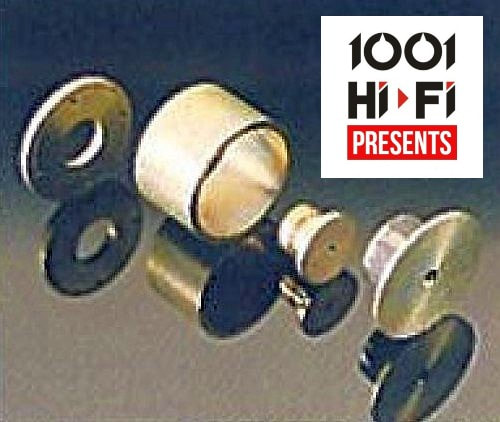

Mounted on a sturdy diecast aluminum frame, the honeycomb disc woofer is a full 38 cm in diameter to assure efficient bass reproduction. The magnet weighs 3.1 kg and is 200 mm in diameter with high flux density of 14,800 gauss. The 75 mm wide voice coil employs a glass fiber reinforced polyamide bobbin and polyamide self-adhesive coil which allow the woofer to withstand temperatures of up to 250*C. This contributes to the high-power handling and great efficiency of 92 dB/W/m. The 8 cm Honeycomb Disc Midrange is using a direct-coupled voice coil 50 mm in diameter capable of maintaining pistonic motion up to 10 khz. The unit is mounted in a diecast aluminum frame for extra stability. For high frequencies there is a 2.8 cm Honeycomb Disc Tweeter. Crossing over at 4 kHz, this remarkable tweeter extends response up to 38 kHz (-16 dB). Its unusual diaphragm is made of laminated mica, 20 microns thin. To bring out the best in individual driver performance, careful attention was paid to waveform linearity in the crossover network. Technical specifications: 3-way, 3-speaker, bass-reflex | Impedance 6 ohms | Input power: 130W (DIN), 300W (Music) | Frequency range: 27Hz-38kHz (-16dB), 35Hz-35kHz (-10dB) | Crossover frequency: 750/4000 Hz | Dimensions: 540x820x415 mm | Weight: 50 kg. | Available in grey (S version) or walnut veneer enclosure (M version). | Price in 1983: 5400 DM/pair (Germany).

Mounted on a sturdy diecast aluminum frame, the honeycomb disc woofer is a full 38 cm in diameter to assure efficient bass reproduction. The magnet weighs 3.1 kg and is 200 mm in diameter with high flux density of 14,800 gauss. The 75 mm wide voice coil employs a glass fiber reinforced polyamide bobbin and polyamide self-adhesive coil which allow the woofer to withstand temperatures of up to 250*C. This contributes to the high-power handling and great efficiency of 92 dB/W/m. The 8 cm Honeycomb Disc Midrange is using a direct-coupled voice coil 50 mm in diameter capable of maintaining pistonic motion up to 10 khz. The unit is mounted in a diecast aluminum frame for extra stability. For high frequencies there is a 2.8 cm Honeycomb Disc Tweeter. Crossing over at 4 kHz, this remarkable tweeter extends response up to 38 kHz (-16 dB). Its unusual diaphragm is made of laminated mica, 20 microns thin. To bring out the best in individual driver performance, careful attention was paid to waveform linearity in the crossover network. Technical specifications: 3-way, 3-speaker, bass-reflex | Impedance 6 ohms | Input power: 130W (DIN), 300W (Music) | Frequency range: 27Hz-38kHz (-16dB), 35Hz-35kHz (-10dB) | Crossover frequency: 750/4000 Hz | Dimensions: 540x820x415 mm | Weight: 50 kg. | Available in grey (S version) or walnut veneer enclosure (M version). | Price in 1983: 5400 DM/pair (Germany).

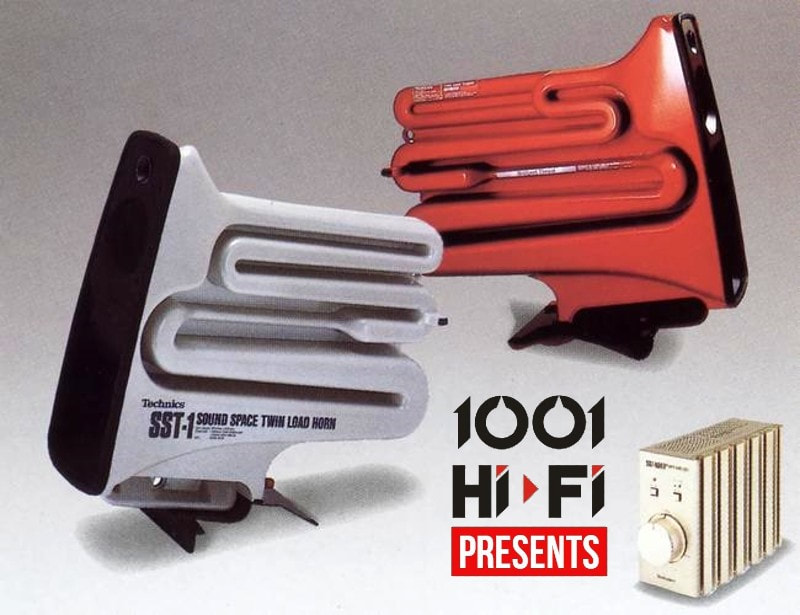

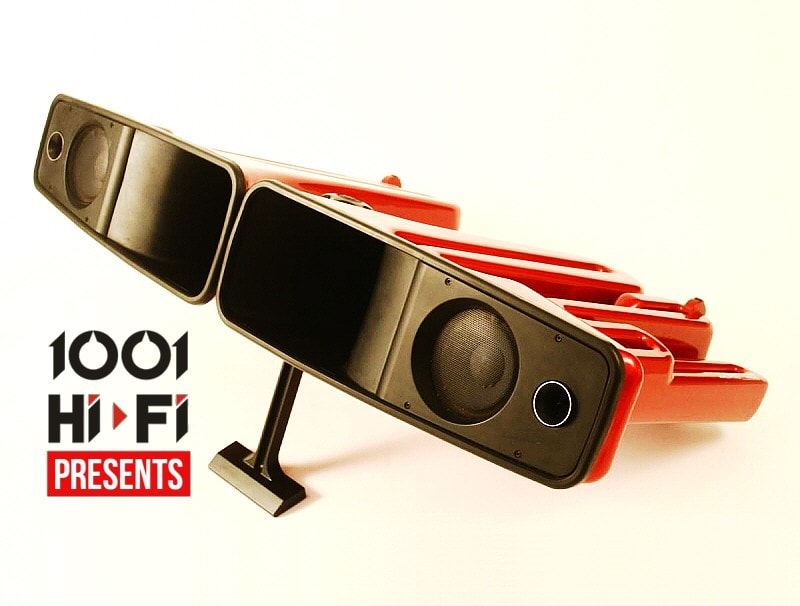

TECHNICS SST-1 (JAPAN 1988)

The SST-1 was a "Twin Loaded-Horn Speaker System" introduced by Technics in 1988, that achieved a high reproduction quality with higher efficiency and lower distortion. This unique form was structured from flow lines using a unique acoustic method by applying computer simulation technology. Compared with conventional back-loaded horns, the twin loaded horns of the SST-1 smoothed sound pressure frequency response in the midrange and high frequencies, thereby further improving reproduction capability with high efficiency and low distortion, which are characteristics of horn speakers. This also made possible the clear and energetic reproduction of deep bass. In addition, the speaker used a “brilliant throat” construction in which part of the horn was narrowed in order to prevent deterioration in sound quality. This also functioned as an acoustic filter blocking the emission of undesired midrange and high-frequency sound, which have extensive distortion. These synergistic effects dramatically improved the acoustic characteristics, from the high frequencies to bass. The SST-1 was equipped with a 5cm tweeter and a 14cm bass unit coupled to the twin horn Labyrint (one 3.2 m and one 2.6 m long). The SST-1 could be used as an independent loudspeaker or as part of a package speaker system, including SST-40WT 20W dedicated amplifier and SST-25HZ Exiter (subwoofer) with its own power drive, the SST-150WT. There were available three-color variations: metallic black, pearl silver, and metallic red. The SST-1 could be used independently on a dedicated stand or you could join two units and add a stand for horizontal use. This system is part of the permanent collection of the Museum of Modern Art in New York. Specification: 2-way Twin-Load Horn Speaker System | Woofer: 14cm cone type chitin diaphragm, Tweeter: 5cm horn type | Power 80W (DIN), 180W (Music) | Impedance: 6ohm | Output sound pressure: 92 dB/W/m | Frequency range 55 Hz-20,000 Hz | Dimensions: 570x650x190 mm | Weight: 12 kg.

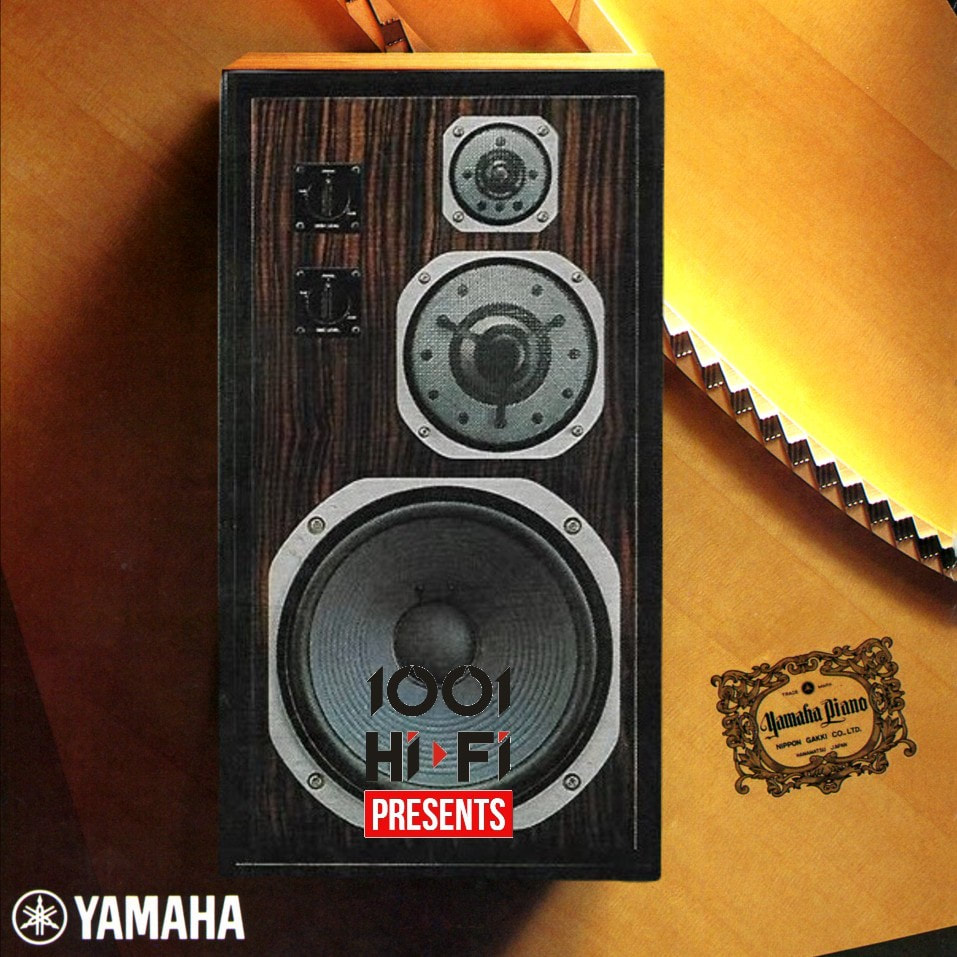

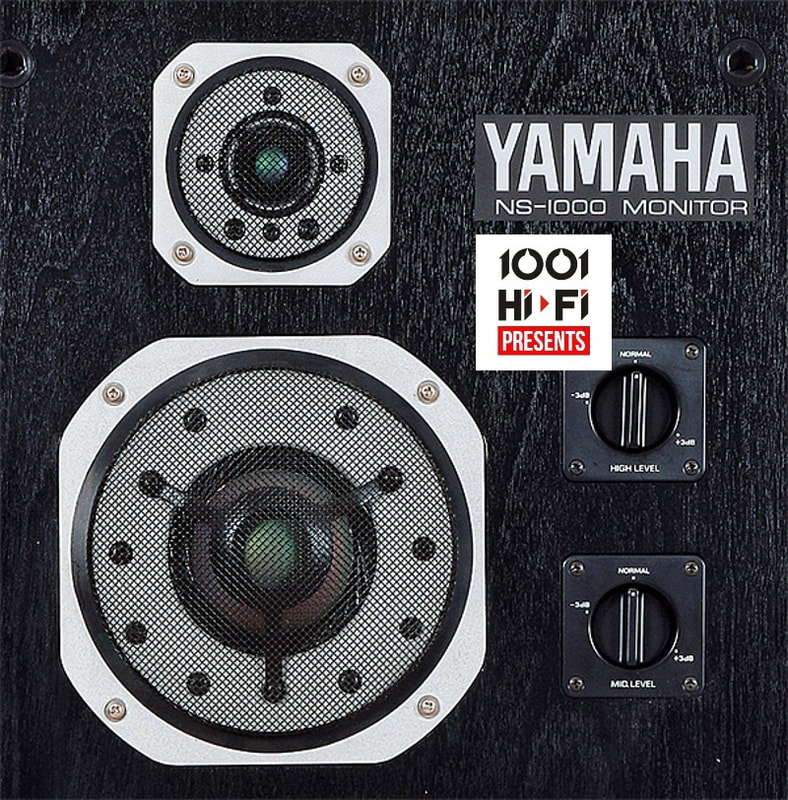

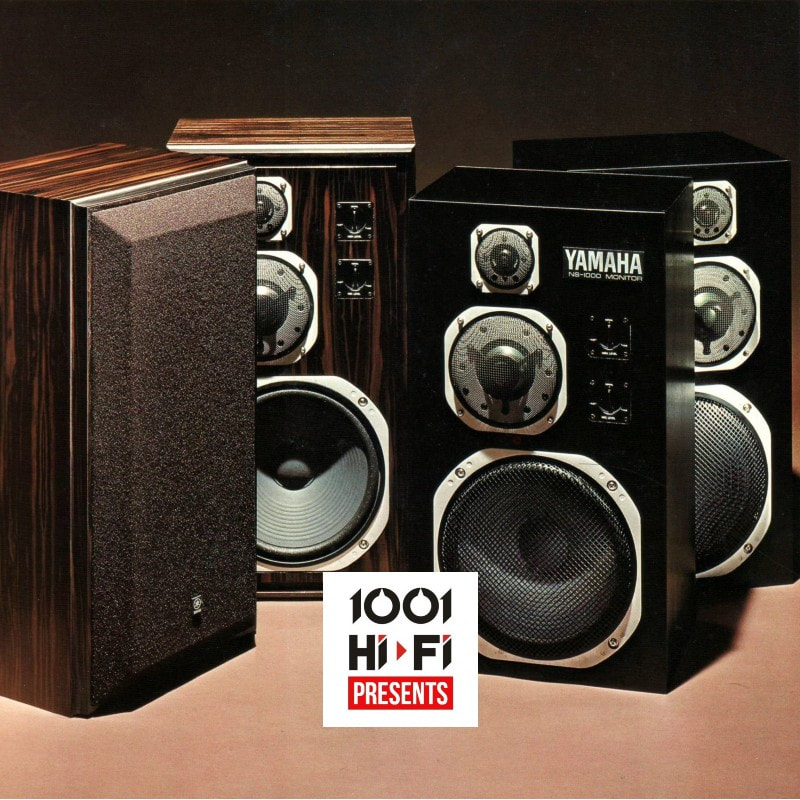

YAMAHA NS-1000/1000M (JAPAN 1974)

The world’s first pure beryllium diaphragms in a Yamaha masterpiece, highly acclaimed by audiophiles and sound professionals.

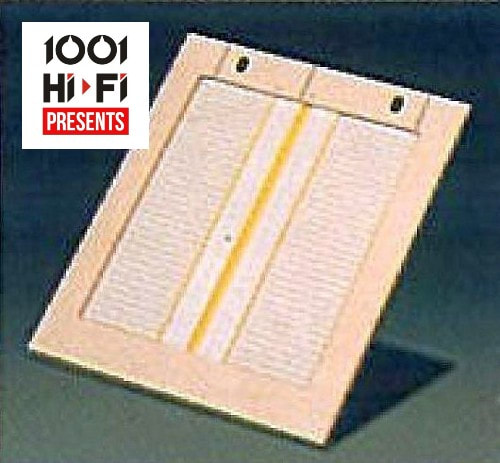

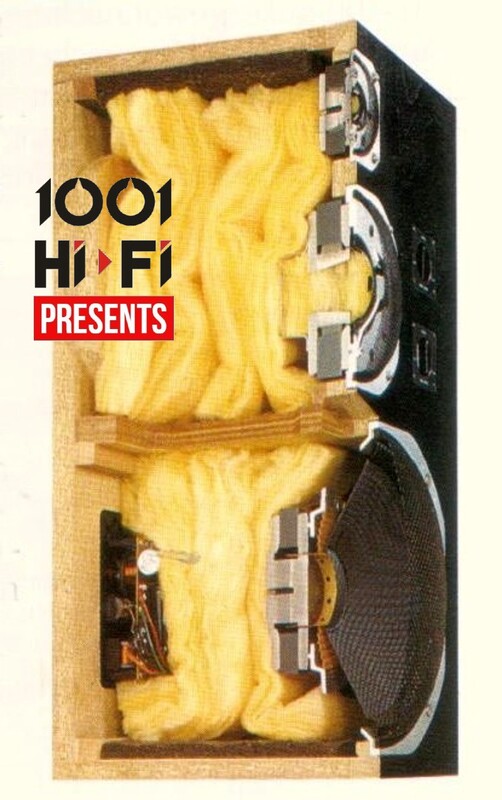

The NS-1000M was the world’s first speaker system to have diaphragms made of beryllium of 99.99% purity — previously considered unobtainable — in its midrange and tweeter. The speaker offered the accuracy and clarity of audio reproduction made possible only by beryllium diaphragms that have an excellent transient response, and earned critical acclaim both at home and overseas immediately after it hit the market in 1974. It was adopted as a studio monitor speaker by the Swedish national broadcasting corporation in 1976, and by the Finland national broadcaster with 200 units ordered in 1978. Even after its successors, the NS-1000X and NS-2000, were introduced, the NS-1000M remained popular and had sold more than 200,000 units over a period of 23 years — before the production of beryllium diaphragms ended and the marketing of the legendary speaker was discontinued in 1997.

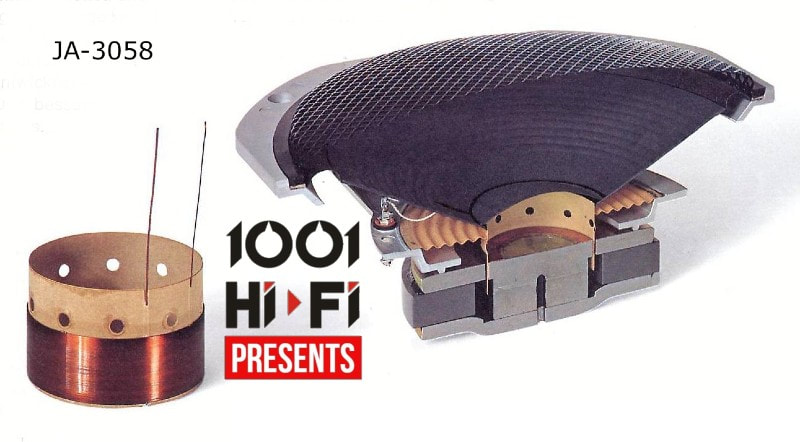

Yamaha developed the world's first hard-dome drivers with beryllium diaphragms — the JA-0801 8.8 cm midrange and the JA-0513 3.3 cm tweeter. Beryllium, considered as the ideal diaphragm material for its hardness, lightweight (low density), and stiffness, was extremely difficult to be molded into a diaphragm. Yamaha overcame the challenge of processing beryllium with its proprietary electron-beam vacuum vapor deposition method. The overwhelming sense of spaciousness and clarity made possible by the beryllium diaphragms that took advantage of the metal's sound velocity (higher than that of any other practical metal) shattered the perception people had of speakers — so much so that the NS-1000M, the first speaker system to feature beryllium diaphragms, earned wide acclaim from audiophiles and critics worldwide. Later, the NSX-10000 released in 1986 came equipped with GC beryllium diaphragms made of giant beryllium crystals, and the GF-1 introduced in 1991 featured forged beryllium diaphragms. Until the production of all beryllium diaphragms was discontinued in 1997, a hard-dome driver for Yamaha was synonymous with a beryllium-dome driver.

Positioned as a high-end unit for home use and priced at 145,000 yen at the time of its release, the NS-1000 featured an ebony luxury urethane paint finish exterior, while the NS-1000M, priced at 108,000 yen and aimed at use from the home to the studio, sported a birch semi-gloss black paint finish. With a somewhat large thick-walled cabinet and removable saran net, the NS-1000 weighed in at 39kg, 8kg heavier than the 31kg NS-1000M. As is evident from the difference in price, the cabinet finish of the NS-1000 was lavish enough to rival that of a luxury wood grain piano, but the fearless black design and overwhelming cost-performance of the NS-1000M made it the focus of popular attention. The upgraded NS-2000 released in 1982 and the NS-1000X released in 1986 reinforced the reputation of the original machine, and in the 23 years until the end of all beryllium diaphragm unit production in 1997 it was a long-lasting hit with more than 200,000 units sold.

The NS-1000M was the world’s first speaker system to have diaphragms made of beryllium of 99.99% purity — previously considered unobtainable — in its midrange and tweeter. The speaker offered the accuracy and clarity of audio reproduction made possible only by beryllium diaphragms that have an excellent transient response, and earned critical acclaim both at home and overseas immediately after it hit the market in 1974. It was adopted as a studio monitor speaker by the Swedish national broadcasting corporation in 1976, and by the Finland national broadcaster with 200 units ordered in 1978. Even after its successors, the NS-1000X and NS-2000, were introduced, the NS-1000M remained popular and had sold more than 200,000 units over a period of 23 years — before the production of beryllium diaphragms ended and the marketing of the legendary speaker was discontinued in 1997.

Yamaha developed the world's first hard-dome drivers with beryllium diaphragms — the JA-0801 8.8 cm midrange and the JA-0513 3.3 cm tweeter. Beryllium, considered as the ideal diaphragm material for its hardness, lightweight (low density), and stiffness, was extremely difficult to be molded into a diaphragm. Yamaha overcame the challenge of processing beryllium with its proprietary electron-beam vacuum vapor deposition method. The overwhelming sense of spaciousness and clarity made possible by the beryllium diaphragms that took advantage of the metal's sound velocity (higher than that of any other practical metal) shattered the perception people had of speakers — so much so that the NS-1000M, the first speaker system to feature beryllium diaphragms, earned wide acclaim from audiophiles and critics worldwide. Later, the NSX-10000 released in 1986 came equipped with GC beryllium diaphragms made of giant beryllium crystals, and the GF-1 introduced in 1991 featured forged beryllium diaphragms. Until the production of all beryllium diaphragms was discontinued in 1997, a hard-dome driver for Yamaha was synonymous with a beryllium-dome driver.

Positioned as a high-end unit for home use and priced at 145,000 yen at the time of its release, the NS-1000 featured an ebony luxury urethane paint finish exterior, while the NS-1000M, priced at 108,000 yen and aimed at use from the home to the studio, sported a birch semi-gloss black paint finish. With a somewhat large thick-walled cabinet and removable saran net, the NS-1000 weighed in at 39kg, 8kg heavier than the 31kg NS-1000M. As is evident from the difference in price, the cabinet finish of the NS-1000 was lavish enough to rival that of a luxury wood grain piano, but the fearless black design and overwhelming cost-performance of the NS-1000M made it the focus of popular attention. The upgraded NS-2000 released in 1982 and the NS-1000X released in 1986 reinforced the reputation of the original machine, and in the 23 years until the end of all beryllium diaphragm unit production in 1997 it was a long-lasting hit with more than 200,000 units sold.